Our Biomass CHP Units

The compact and clean solution

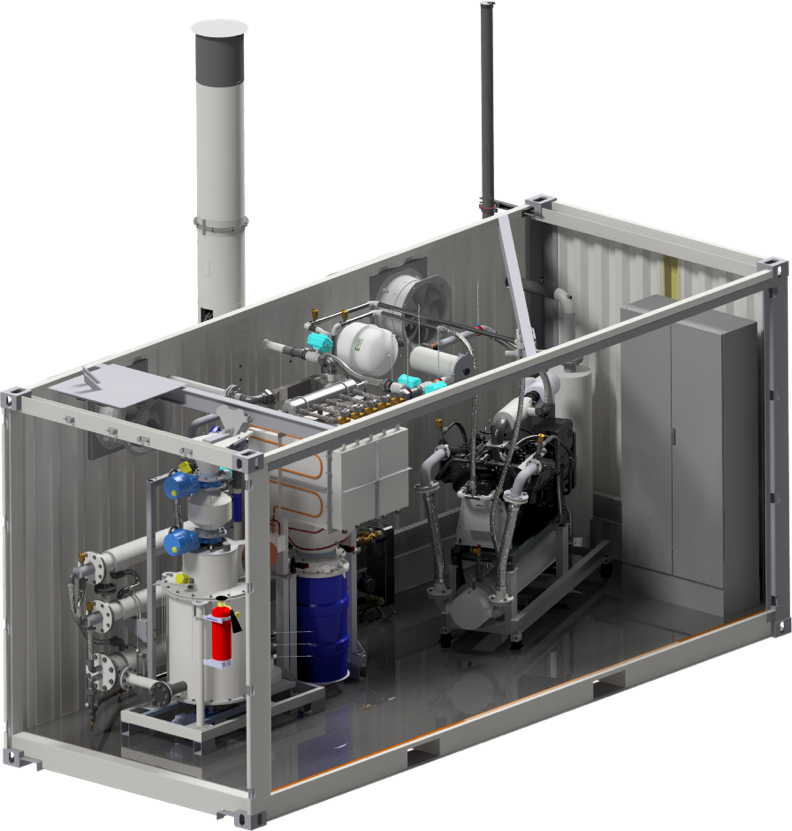

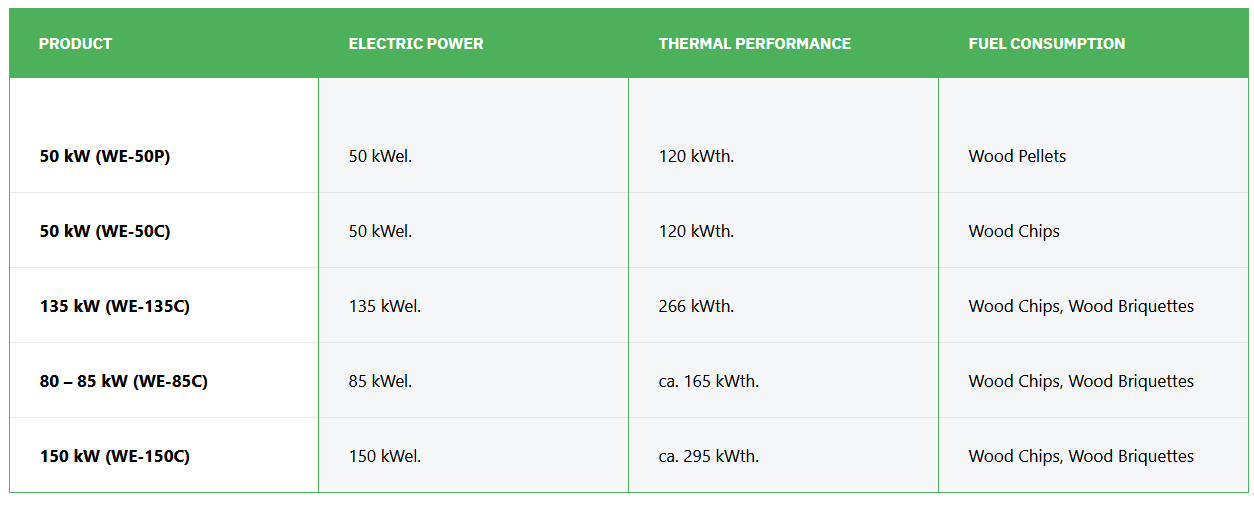

50 kW Pellets (WE-50P)

The WE-50P is the compact and clean solution for wood power generation for industry and commerce!

Nominal power

50 kWel and 120 kWth

Fuel

Wood pellets, 6 mm, DIN EN Plus A1 quality

Fuel consumption

Ca. 42 – 44 kg/hrs*

Total efficiency

85 %*

MORE DETAILS

Electric efficiency

25 %*

Thermal efficiency

60 %*

Max. Flow/return temperature

90 °C / 60 °C (5000 l/h) Return max. 65 °C

Nominal voltage

400 V, 200 V

Operation hours

Up to 8000 hrs/a**

Control unit

Fully automatic operation, optional 24/7 remote monitoring

Case type

20 ft HC-Sea container, L 6,058 m x W 2,438 m x H 2,869 m

Commissioning duration

8 – 72 hrs.**

*depending on fuel quality **depending on maintenance and fuel quality

50 kW Wood Chips (WE-50C)

The WE-50C uses inexpensive wood chips. After wood gasification, a CHP unit provides for the generation of electricity and heat, as in the WE-50P. The plant is particularly suitable for forestry and agriculture.

Nominal power

50 kWel and 120 kWth

Fuel

Wood chips EN14961-1, P16-P45, 8 % — 10 % humidity

Fuel consumption

Ca. 45 – 48 kg/hrs*

Total efficiency

85 %*

MORE DETAILS

Electric efficiency

25 %*

Thermal efficiency

60 %*

Max. Flow/return temperature

90 °C / 60 °C (5000 l/h) Return max. 65 °C

Nominal voltage

400 V, 200 V

Operation hours

Up to 8000 hrs/a**

Control unit

Fully automatic operation, optional 24/7 remote monitoring

Case type

20 ft HC-Sea Container, L 6,058 m x W 2,438 m x H 2,869 m

Commissioning duration

Ca. 2 days**

*depending on fuel quality **depending on maintenance and fuel quality

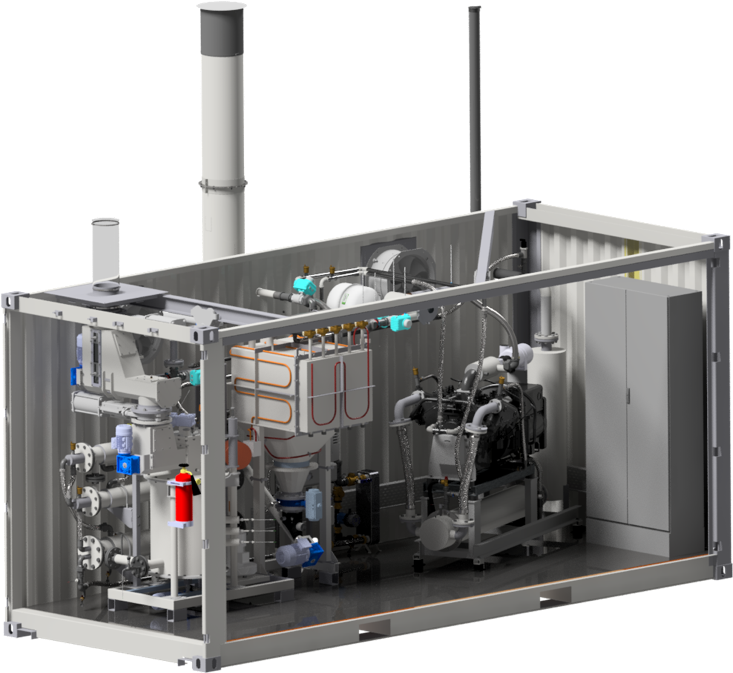

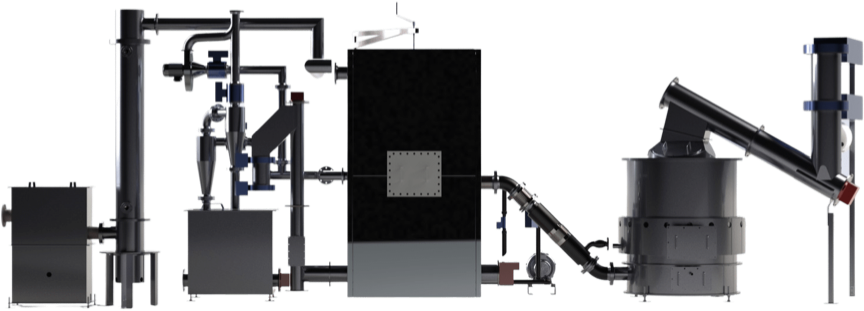

135 kW Wood Chips, Briquettes (WE-135C)

The 135 kW plant WE-135C has proven itself very well and is one of the 'classics'. Very suitable for forestry and wood processing, hotels (also with spa), breweries, dairies, nurseries and heating networks. In addition to wood chips, this plant can also be operated with wood briquettes (pressed wood chips from wood residues).

Nominal Power

135 kWel and 266 kWth

Fuel

Wood Chips 30-70 mm

Fuel consumption

Ca. 95 kg/hrs*

Total efficiency

83,3 %*

MORE DETAILS

Electrical efficiency

32 %

Thermal efficiency

55,4 %

Max. Flow/ return temperature

80-88 °C / return max. 70 °C

Rated Voltage

400 V

*dependent on fuel quality **dependent on maintenance and fuel quality

GALLERY

Our Products in Use

Mühlbach / South Tyrol

Our wood gas plant for a glulam manufacturer in Mühlbach/South Tyrol went into service in October 2013. The special feature: The plant is not fired with wood chips but with wood briquettes. This required extensive research and testing in advance. Our wood gas plant runs in continuous operation day after day, year after year. It is reliable, low-maintenance and an indispensable part of our production process.

Dalquhandy / Scotland

A larger plant equipped with 8 modules is located in Scotland. This has been in operation since summer 2017 and reliably produces 1 MW of electricity and the corresponding heat output.

Bamberg/ Germany

In Bamberg, an adventure pool is heated by means of our wood-fired power generation plant. The plant is purely heat-led. It has been providing reliable service since 2011.

Kushima Hospital / Japan

In 2021, a pellet-fired WE-50P CHP and high-efficiency chillers/heaters were installed at Kushima Hospital.

Fields of Application

Electricity and heat production can be used in different ways, depending on your needs. Here are a few examples.

PROJECTS WITH PROCESS HEAT

Mühlbach, South Tyrol

A manufacturer of glulam beams in Mühlbach, South Tyrol, connected a 125 kWel plant to the grid in October 2013 and is currently supplying 139 kWel.

The special feature: The plant is not fired with wood chips but with wood briquettes.

Annual operating time: +8,600 hours

Wegscheid, Germany

The prototype plant has been in operation in Wegscheid since 2009 and generates 125 kWel.

The electricity is fed into the utility grid, the heat is sold as process heat to three neighboring companies and used for heating.

PROJECTS WITH COOLING

Sampeyre, Italy

In early 2014, a 125 kW + 65 kW plant was commissioned in Sampeyre, Italy. The customer, a salami producer, uses the electricity and converts the generated heat into cold.

Special feature: “Hot version”, heat is extracted at 105 °C.

Annual operating time: +8,200 hours

Are you interested?

Contact us now free of charge and without commitment. With a short information about your needs, the location of your company and what your expectations are, we can advise you on how a biomass CHP system can be used in your company.

FUELS

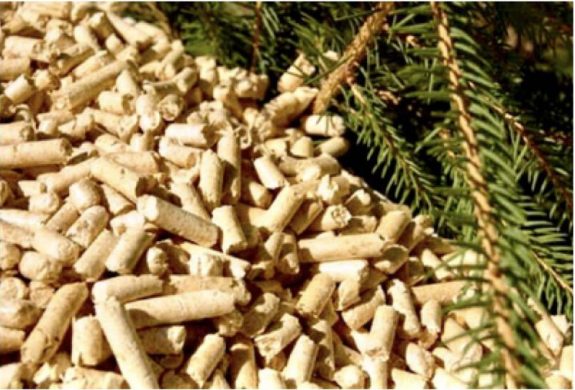

Pellets

Wood pellets are compressed wood shavings that are mainly made from sawdust. As they have a uniform shape and high quality, they are very suitable for our biomass CHP plants. The pellets are transported to the gasifier via a hose conveyor.

Advantages

- Space-saving alternative, as the pellets are ready for processing

- High standardization and therefore good gasification

- The clean and tidy alternative

- Less service and maintenance work for the machines

Wood Chips

Wood chips are produced from residual wood, e.g. from forest wood, sawmill by-products or industrial waste wood. Wood chips are particularly suitable as fuel for combined heat and power plants in rural areas, as more space is required to store the material. The wood chips are transported to the gasifier by a screw conveyor, where they are converted into wood gas.

Advantages

- Inexpensive material

- Easy to use for sawmills or other woodworking industries

- Supplier market is very developed and therefore the deliveries are easier to plan

Wood Briquettes

Wood residues from wood processing, such as planing or sawdust, are compressed into wood briquettes.

Advantages

- Inexpensive material

- Easy to use for sawmills or other woodworking industries

- Supplier market is very developed and therefore the deliveries are easier to plan

Do you have questions?

We have compiled the answers to important questions for you.

Is a biomass CHP unit worthwhile for my company?

A biomass CHP unit with wood-fired power generation is particularly worthwhile for companies that require constant large amounts of thermal energy for their operations – even in summer. This is because a biomass cogeneration plant is only maximally economical if it operates at full load for a certain number of hours per year. Alternatively, excess heat energy can also be converted into cooling energy in the summer.

What are the requirements for the use of a CHP unit?

Our CHP units generate electricity and heat all year round. Therefore, there should be sufficient electricity and heat demand throughout the year.

Technical requirements:

To ensure a smooth start-up of the system on site, the customer will provide the following on-site installations:

- Foundation with sufficient access to all system components

- Sufficient building (if installed indoors)

- Sufficient air supply with adequate circulation rate (if installed in the building)

- Three-phase connection with 400 V, 100 A

- External fuel silo in close proximity to the E5 unit.

- Space for conveyors and storage

- Space for ash house for ash discharge

- Heat extraction (5000 l/h ∆T 25°C)

How much does a biomass CHP unit for wood-fired power generation cost?

A plant for wood-fired power generation is a very individual solution, where the investment costs and also the running costs can be very different. In addition, the various fuels and, if applicable, their processing also result in varying costs. Depending on the application in the process or in the building, different subsidy amounts also come into play, so that a generalization of the total costs is hardly possible.

What fund support options are available?

Companies that use wood-fired power generation by means of a biomass cogeneration plant to generate energy and thus make a contribution to climate protection receive financial support at many levels in Germany. In addition to the feed-in tariff for surplus electrical energy, the German Federal Ministry of Economics and Export Control (BAFA) supports corresponding projects.

The Kreditanstalt für Wiederaufbau (KfW) also supports climate-friendly rethinking with development loans and repayment subsidies of up to 55 percent of the eligible costs. And the individual German states and regions also reward the use of biomass CHP units as progressive and environmentally friendly energy generation.